You can share

- Share to Facebook

- Share to Google+

- Subscribe to our

- Share to Linkedin

- Share to Twitter

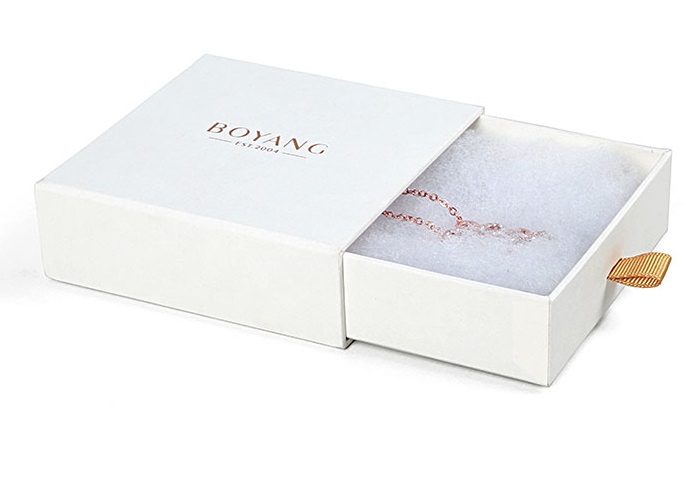

With the development of printing technology, people have higher requirements for the production of jewelry packaging boxes. They require bright colors and textures in materials. In terms of levels, they not only need to reflect the light and dark levels of the plane but also need to have a three-dimensional effect. Concave-convex printing can increase the three-dimensional level of the product.

What is the embossing process? The embossing process is a process in which pressure is applied from the back of the paper to make the surface swell. The prefabricated concave-convex plate of the design drawing and the pressure effect makes the surface of the paper form a three-dimensional effect that is higher or lower than the plane of the paper. Concave-convex, also known as embossing, is a common technique in processing customized jewelry packaging boxes. The purpose is to emphasize a certain part of the design, highlight the key points, and make the picture richer in layers.

The embossing process needs to consider the thickness and toughness of the paper, because the deepest and shallowest parts of the embossment need a certain drop, too thin is not suitable, and the paper that is too brittle is easy to burst to the edge. Generally, more than 220g is required, and the higher the toughness, the better. The lines of the design draft should not be too fine and dense. Generally, the lines should be more than 0.2mm, and the spacing between graphics should be at least 2mm.

Concave-convex features embossed various convex graphics and patterns, showing different shades of ways, with a clear sense of relief, which enhances the three-dimensional sense and artistic appeal of printed matter.

1. Make stereo modeling pattern text, and add decorative artistic effects.

2. Improve the grade of commodities and increase the added value of commodities.

3. The advanced and fine concave-convex shape is difficult to imitate and has a considerable anti-counterfeiting effect.

1. Concave-convex embossing is the transplantation and application of relief art in printing. Its printing plate is similar to the arch flower method used in woodblock watermarking in my country.

2. When printing, no ink is used but the pressure of the printing machine is directly used for embossing. The operation method is the same as that of general letterpress printing, but the pressure is higher. If the quality requirements are high, or the paper is relatively thick and hard, hot pressing can also be used, that is, the current is connected to the metal base plate of the printing machine.

3. Concave-convex embossing technology has a long history of application and development in my country. As early as the beginning of the 20th century, hand-engraved printing plates and manual embossing processes were produced; in the 1940s, it developed into hand-engraved printing plates and mechanical embossing processes; in the 1950s and 1960s, an independent system was basically formed.

4. In recent years, the high-grade and multi-variety development trend of printed matter, especially packaging and decoration products, has promoted the popularization and improvement of embossing technology, and the production of printing plates and embossing equipment is gradually realizing semi-automation and full automation. Fully automatic printing and concave-convex embossing production lines including multi-color printing units have been realized abroad.

The above is the concave-convex process used in customizing jewelry packaging boxes. Jewelry box factories will also use a variety of other processes in production, and we will learn about them one by one later.